Small scale producers of a soft, sharp cheese, called pultost in Norwegian, in the counties of Oppland and Hedmark in Norway received a status of presidium product at Slow Food’s cheese fair in Bra, Italy on 19 and 20 September 2009.

The laborious work of a cheese producing cooperative called Pultost BA and the Slow Food Foundation in Norway have produced results. The soft, sharp cheese (pultost) is the first presidium product from the eastern part of Norway. Before, Norway had 4 presidium products: wild sheep from the western part of Norway, brown cheese from the western county of Sogn, smoked herring from the northwestern county of Møre and stock fish from Kristiansund.

A presidium is the active part of the Ark of Taste whose objective is to rediscover, register, describe and spread the word about forgotten tastes, drinks and foods. The Slow Food movement has presently about 270 presidium products spread worldwide in the Ark of Taste.

The Norwegian pultost is a very old type of cheese which formerly was produced in most of the country, that is, it was produced from the southern tip of the country up to the northern town of Mo i Rana. Now, the cheese is mainly produced in the counties of Oppland and Hedmark.

We went to a mountain farm, called Fjellsetra, in order to see how the cheese is made in the vicinity of Hugulia located in Nordre Land in the county of Oppland. There, we met Bjørg Karin Hagen, who’s the manager of Pultost BA, a cooperative of several small scale producers of pultost in Hedmark and Oppland.

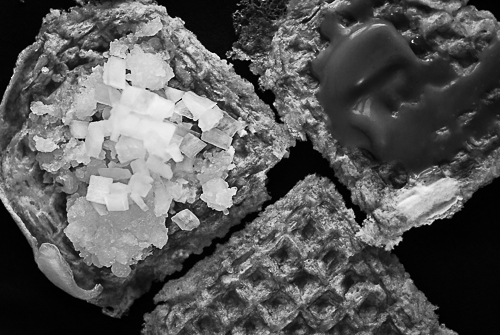

Buttermilk waffle with pultost and chopped onion

Bjørg Karin received us at her mountain farm on a bright autumn day in September just a week before she was going to Italy. After having invited us inside her guest hut, she brought us buttermilk waffle, pultost, soft, sweet, brown whey-cheese, chopped onion and coffee.

For those not in the know, buttermilk is a waste product from churning cream into butter.

Note! Adding chopped onion to pultost is recommended for beginners

Thereafter, she let us know about the basics of pultost. Making this type of cheese naturally starts with what the free-ranging cows are eating, which will influence the taste of the final product. Then, after having milked the cows, the milk has to undergo separating, souring, separating whey and cheese mass, drying and maturing.

The sweet milk is separated into cream and skimmed milk. 11 litres of skimmed milk is required in order to make one kilo of cheese, Bjørg Karin explained. Soured sweet milk (milk which has been warmed up to 20°C at a pH of 4.3 before being cooled down rapidly to 3-5°C) is added to the skimmed milk.

Separating whey and cheese mass

The soured, skimmed milk is warmed up to 50°C, then, the milk is whipped, before it is let to coagulate and turn into a cheese mass. After the cheese mass has been extracted, the whey stays behind. In fact, whey is a waste product or co-product from the making of white cheese. However, whey has been used in production of brown cheese and soft, sweet, brown whey-cheese for ages.

Drying

The cheese mass is compressed and then hung to dry in some type of porous cotton fabric in order to let out the whey. When it seems dry, firm and it leaves a little humidity when you hold it in your hand, it is ready for the next step. Bjørg Karin gave us a demonstration by holding a clump of cheese mass in her hand and showing us that the cheese mass had left her plastic glove humid. The last characteristic was a sign that everything was as it should be.

Fermentation and maturing

How long time does the cheese require to mature, we asked. That depends on many factors, was the answer. The cheese is matured at 25°C and it is checked daily. When the consistency, flavour, colour, and taste is like the producer want them to be, the cheese is ready. Then, salt amounting to about 5% of the total weight is added to the cheese in order to stop the fermentation in addition to adding taste. Caraway and possibly even more salt is added in order to set the taste of the cheese.

Sales and distribution

The cheese is sold at stands and fairs and from her own mountain farm at Hugulia. Bjørg Karin is one of a few small scale producers who can say that sales and distribution is no problem since everything which she produces is sold.

What she’s doing in order to achieve this, we don’t really know. After having stayed a few hours at her mountain farm, we think that her great ability to spread the word about the taste, culture and enjoyment are contributing factors. We think her customers buy her cheese and get a good story and a great experience, as well. That is, the customers get more than they give.

We gave our thanks for being allowed to visit her, and gave her our best wishes for her trip to the cheese fair in Bra, Italy. There, she has received the final confirmation that the Norwegian pultost has been accepted as a presidium product since it is produced according to old, tried and true methods.

Producers which participate in Pultost BA are the following :

- Avdem Gardsysteri

- Brimi Seter

- Holen Gardsysteri

- Høgda Gardsmeieri

- Bjørg Trønnes

- Helen Davey

- Bjørg Karin Hagen.