We went to visit Oana in the city of Sfântu Gheorghe where we were met by her and her husband, who is running a bike workshop next to her chocolate workshop. While he was cleaning a chocolate tempering machine by melting the remaining chocolate with heat guns, Oana showed me how she makes chocolate.

Chocolate tempering machine

Chocolate tempering machine

Spots of cocoa butter are visible on the surface of the chocolate if not done correctly, a phenomenon, which is called crystallisation. An interesting video about crystallisation can be watched here. Oana wants the surface to be shiny, smooth and brown, which she obtains by extracting liquid chocolate when it has the correct temperature. She was using an infrared thermometer to measure the temperature of the liquid chocolate.

I’ve been to three other chocolate makers in the county of Hargitha in Romania, one in Norway and another one in Spain, but Oana is a the only one who makes chocolate from cocoa beans, called bean to bar and she imports the beans from Peru and Nicaragua. This means that she needs to process the cocoa beans before she can use them to make chocolate.

Quote: Bean to bar chocolate is chocolate that is made from scratch by the same producer, starting from the raw cacao beans and ending with the finished chocolate bars and treats. This process allows the chocolate maker to control every aspect of the chocolate making, such as roasting, grinding, conching, tempering, and moulding. Bean to bar chocolate is often more flavourful, nuanced, and ethical than mass-produced chocolate. It reflects the artistry and craftsmanship of the maker and the quality and origin of the cacao. Unquote.

She roasts the cocoa beans in an oven to develop flavour, kill bacteria and loosen shells, next she’s cracking the shells and blowing them away, leaving the nibs behind. Next, she grinds the nibs into a thick paste known as “cocoa liquor”.

Grating cocoa butter above melted chocolate and mixing them together.

Grating cocoa butter above melted chocolate and mixing them together.

Mixing liquid chocolate with tahini and salt

Mixing liquid chocolate with tahini and salt

She melted cocoa butter and poured it into a small tank with liquid chocolate. Next, she poured crushed tahini on top of the mixture, finally she added a little salt. Afterward, she stirred everything together to make a chocolate paste.

Thereafter, Oana inserted a knife in another chocolate bath, put it in a fridge and took it out after some time and found that the liquid chocolate needed to stay longer in the heater. Only for a demo, she poured the chocolate in a mould, scraped off excess liquid chocolate and shook the form to get rid of bubbles. Due to limited time, she would put pistachio in the liquid chocolate later.

Pouring liquid chocolate in a form and turning it upside down

Pouring liquid chocolate in a form and turning it upside down

Chocolate bars on pistachio with and without packaging

Chocolate bars on pistachio with and without packaging

I got to taste the chocolate with pistachio, and it was delicious.

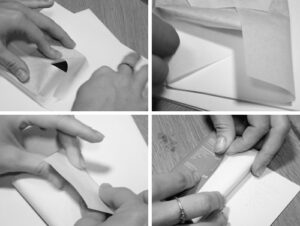

Oana also showed me how she folds paper around her chocolates, and she made it seem easy.

Folding paper around a chocolate bar

Folding paper around a chocolate bar

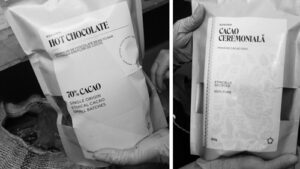

Hot chocolate and ceremonial cocoa

Hot chocolate and ceremonial cocoa

Her company is called Kokowa and I asked her if it was her last name. Instead, it’s a pun on cocoa and Wanna, her name in Romanian.

In addition to being an excellent chocolate maker, she’s also good at punning. She’s also producing various types of peanut butter as shown below, they are called peanutter and pawnutter where the last one is peanut butter for dogs. In addition, she’s selling hazel butter as hazelnutter, almond butter as almonutter, cashewbutter, caju in Romanian, as cajunutter.

Peanut butter collection

Peanut butter collection

The Krausz chocolate company is located some distance from this one.