We went to Pálinka Jamy where Jamy derives from the first names of the children of the family, in the town of Odorheiu Secuiesc where we were met by the owner, Rezső Szőcs. He told us that their company was located in a house from 1918 and it was founded in 2005. Having a large veranda, a well-lit cellar with tanks containing various types of fruit mash and the ground floor with an office, the distillery, a tasting room and a packing room, all seemed clean and newly refurbished. It’s a family-run company, that is, it’s run by Mr Rezső and his wife, while their children go to school.

His grandmother was the boss in the family and she stayed for 48 hours in the distillery, controlling the pálinka to prevent mixing by the distillery workers. His father used old technology to make pálinka and he didn’t enter any competitions.

Mr Rezső told us that brandy was forbidden in communist times, but people made it anyway. However, it was of low quality and people kept everything. Unfortunately, the tradition has continued such that people still use poor-quality fruit for making pálinka. Instead, they use the best fruit for pálinka in order to show everyone that they make high quality pálinka.

Since this town is located in the Hungarian-speaking part of Romania, Mr Rezső and his family are part of Szekler society, who is characterised by knowledgeable, hardworking people, never giving up, a sense of honour and Hungarian spirit.

Having sort of grown up with pálinka, Mr Rezső wanted to start his own distillery. Both he and his wife have attended distillery courses. They met a designer, who’s selling stoves and boilers for distilleries, in Hungary at one of the courses. Helping them helps him too and they can call him when they need help. They have visited many distilleries in order to learn more and they have bought a new automated distillery from Kothe destillationstechnik in Germany.

We were first shown the cellar where there was equipment for rinsing fruit and berries and de-seeding fruits like cherries and plums. Upon arrival, all the fruits and berries are rinsed to get rid of dust and impurities, but also natural yeasts to be able to control fermentation themselves. Unfortunately, he has to pay for the complete weight of the fruits even though he has no use for the seeds.

When the fruits and berries arrive at the distillery, they have to stay in the shade because they are fragile and fermentation will start in the sun.

They need 30-40 tons of fruits annually, it’s a good region for growing fruit, but it’s difficult to get enough berries.

They want to give the residues to farm animals, but the farmers say no. So far, they have used it as compost, instead.

In the next room, there were several stainless steel tanks. Mr Rezső told us that they had bought them second-hand from a dairy and they used them for fermenting the fruits and berries.

During our visit, he showed us how he stirred mashes of cherry, raspberry and Williams pear. All the mashes would ferment slowly at 10-15°C and he didn’t add any sugar.

He uses native varieties of apples, removing the seeds and using the pulp for making pálinka. He’s also using Cornelian cherry, which after having been de-seeded, are crushed and the mash is pumped into stainless steel containers.

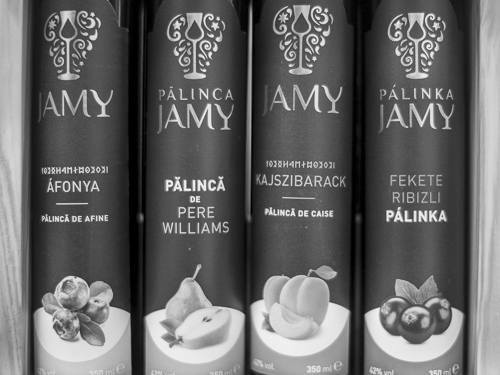

In fact, this distillery buys up 32 types of berries and fruits in all and they are producing 17 types of brandy.

They are recording regularly the state of the mash, date, temperature, degrees Brix , etc. They use taste and smell to decide if the fermentation has finished and they measure degrees Brix, which is a measure of the sugar content of an aqueous solution, by inserting a small amount of the mash to be tested in a hand-held measuring instrument through which one can look.

This video shows how cherries are picked by hand, transported to the distillery, rinsed, de-seeded, fermented, pumped to the distillery and turned into pálinka. For reference, another Romanian distiller is described here. When the mash has fermented enough, it’s pumped up to the distillery where it is heated to 78 °C and the resulting vapour is made to pass a heat exchanger, which condenses the vapour into liquid and ending up in a bucket. They carry the bucket to the next room where they pour the contents into a stainless steel container. The initial alcohol level is 90%, but by adding tap water, they lower it to 42%. A short video showing distillation in a simplified way is shown here.

When we had been shown the distillery and the production room, the labels, the bottles and their medals, it was time to start tasting their products.

While being offered pálinka when one visits someone in Transilvania is like being offered coffee in my country, the tasting was way different from what I’ve been used to. In the first case, we are offered homemade pálinka, which is poured into a shot glass until it’s full. Next, it’s expected that we drink all of it in one go. Instead, Mr Rezső used tulip glasses made for pálinka and he just served a tiny amount in each glass. Finally, we were not expected to swallow all in one go. Instead, we should taste it and enjoy it slowly.

Mr Rezső talked a lot about pálinka competitions and the first time they entered a competition with a plum pálinka, they didn’t win anything. However, they have won a silver medal for another plum brandy and they had won several medals from Quintessence.

We were told that they work very hard to win medals at the competitions, but that they consider their competitors as friends. A friendly competition, in other words.

Like all pálinka distilleries, they are only making pálinka in autumn when fresh fruits and berries are available. The rest of the year they are marketing their products.

After having tasted several of their pálinkas, among them raspberry and plum, it was time to say thank you and goodbye.