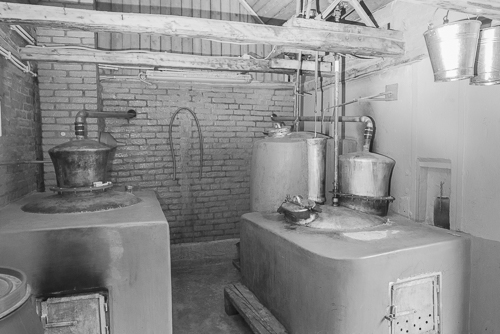

Having arrived at the house of Csaba Csípán, the founder, owner and manager of Csípán Pállinka, he willingly showed us his distillery. The building and techniques he is using to make pálinka date back 200 years, but he has combined traditional techniques with up-to-date technology. Inside a small brick building, the distillery seemed to consist of two copper containers, some tubes and a wood-fired oven to an untrained eye, but as always with technical apparatus, it’s a lot more complicated.

In order to make pálinka, high quality fruit has to be available. Due to its geography and specific micro-climate, this region is most suitable for cultivating fruits. Cultivation of fruits for hundreds of years have given fruits of inimitable flavour and aroma, which make pálinka or fruit brandy from this distillery distinctive.

Next, the fruit has to be mashed, but any stony seeds have to be removed first. Then, the mashed fruit is allowed to ferment in an environment without oxygen for 10 to 15 days. Finally, the fermented mash is heated to 70 °C and the resulting vapour is made to pass a heat exchanger, which condenses the vapour into liquid. This procedure is repeated for a second distillation where an experienced worker has to be present to taste and smell the product. The first part of the second distilling contains copper, while the alcohol content is decreasing continuously during distilling. In the end, the fruit brandy turns sour and can’t be sold. The alcohol content from the second distilling is about 60% +/- 5%, but Mr. Csípán aims for 52%, which he manages by adding water from a well. He has 11 wells and one of them doesn’t give colour to the fruit brandy. When the alcohol content is acceptable, the fruit brandy is filtered and bottled. The remains from the fruits are transported into the basement and sent to a company, which turns it into fertiliser.

Mr. Csípán has the required certificates for making fruit brandy, his production is official, but he has to pay 50% tax on everything he produces. He makes a living for his family from the distillery even though the official market is small and the black market is huge, he’s not willing to compromise on quality, he won’t sell to supermarkets, 10 persons are working part-time, he’s able to triple the production, but he wants his company to grow slowly. He sells his products mainly in Szekler land to restaurants, guesthouses and pubs within a radius of about 20 km.

Three main types of fruit brandy are made at this distillery:

- Wild pear

- Wild blueberries

Combination of 50% cherry and 50% distilled wine. Pour distilled wine on a bed of cherries and leave everything for at least 3 months. The result is brandy on a bed of fruit.